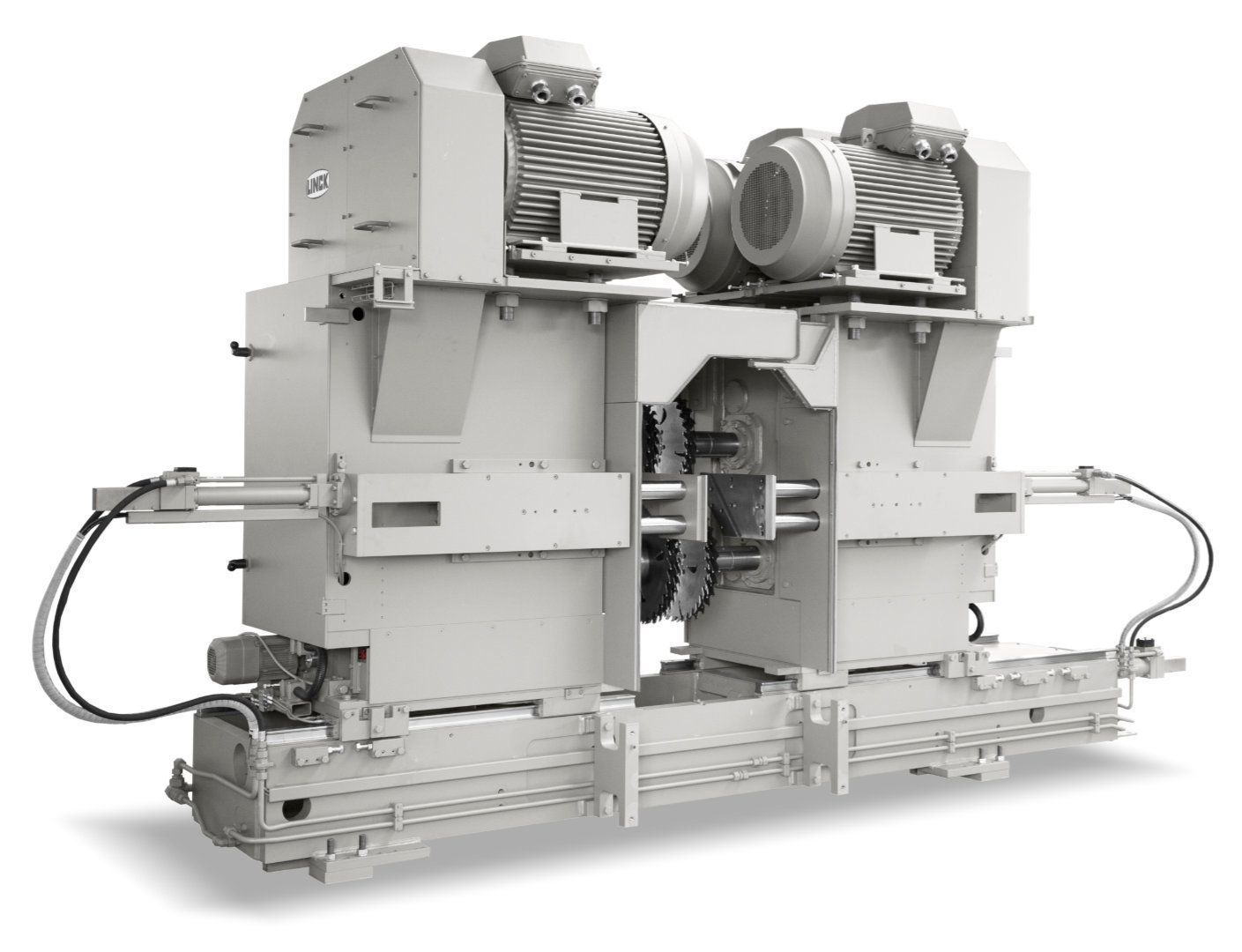

Saw Unit CSMK

Auf einen Blick

Saw arbors

The CSMK saw arbors can be designed with one to three axes per side.

The main saw arbors 1 and 2 are adjusted together with the upper machine frames. Saw sleeves (3 and 4) move on the main arbors 1 and 2 in case the machine is designed with four axes. These saw sleeves are positioned with their own servo cylinders and can have several saw blades with fixed spacing inbetween. The maximum clamping length is between 110 and 150 mm depending on the cutting height. In case the machine is equipped with six axes, the main arbors 1 and 2 are designed as hollow shafts to take the shafts 5 and 6. Adjustment is done by servo axes. A sawblade can be installed on each of these shafts. The number of axes on the right- and left-hand machine side can be independent from each other and range between one and three axes. The maximum equipment of the machine with six axes with independent positioning makes it possible to split the cants into seven products of different dimensions. The fast servo-hydraulic adjustment allows a log to log setting with small cant gaps and is therefore suitable for the processing of unsorted logs.

The robust, vibration resistant frame which takes the two machine housings is the prerequisite for a long lifetime and the excellent lumber dimension accuracy. Width adjustment can either be done by electrically driven ball-screw spindle or hydraulic servo cylinders. Two standard three-phase motors per saw arbor with each 200 kW maximum drive power are used as main drive motors.

Führungsplatten

Für hohe Maßhaltigkeit der Schnittholzprodukte kann das Sägeaggregat CSMK mit Führungsplatten ausgestattet werden. Die Führungsplatten werden mit einer separaten servohydraulischen Achse entsprechend dem jeweiligen Schnittbild auf Position gefahren und sorgen für eine exakte Führung des Holzes.